A programmable DC power supply is a precision DC power supply with a built-in processor (also known as a microcontroller) that allows users to set precise output parameters to meet their specific requirements in an automatic fashion via a script or program on a remote computer.

In a typical product testing application, the output levels of a programmable DC power supply can be changed to follow specialized patterns, known as waveforms or profiles, and switched on and off automatically to verify the product‘s functionality with different power inputs.

6 Unique Features of the Volteq Programmable DC Power Supplies

| Features | Benefits |

|---|---|

| Arduino Micro as the microcontroller | Enables easy and efficient control of the power supply through a widely available and popular microcontroller platform. |

| Full access to the software stack | The Arduino IDE and our source codeallows our customers to easily develop and debug their codes. |

| Multiple digital and analog pins available for input and output control | Enables versatile and flexible control of external devices and sensors, allowing for complex and customizable power supply functionality. |

| 5V and 12V DC outputs as control signal for process control | Provides compatibility with a wide range of devices and applications, expanding the range of potential uses for the power supply. |

| Feedback loop to ensure stable output | Ensures that the power supply maintains a stable output voltage or current, increasing reliability and stability of output. |

| Optional reverse polarity box | Adding reverse polarity capability is relatively straightforward. |

Who Uses Programmable DC Power Supplies?

Programmable DC power supplies are used in research and development, manufacturing, and quality management for automatic process control, testing, calibration, and burn-in of electronic equipment. Customers have used Volteq programmable DC power supplies in a wide range of industries, including aerospace, automotive, telecommunications, bio/medical, analytical instruments, electronics and semiconductor industries.

What Makes Up a Programmable DC Power Supply?

Different programmable power supplies may have different components, but the base elements include a processor, voltage and current programming, voltage and current readback circuitry, and a current shunt. Other common (but optional) features include built-in overvoltage compensation, overcurrent compensation, short-circuit protection, and temperature regulation.

Applications Example:

In this example, the power supply HY3050EP (it could be any other EP model) is used as a high output pulse DC power supply. With custom software, it can generate a square wave output with a variable pulse width for up and down output (in this case the down output is set to be zero). The on and off pulse widths can be set separately, from 1 ms to 1000 ms. The pulsed output is generated with the help of a solid state relay rated for 50A, and controlled with a 5V signal generated by the power supply.

Making Connections

The image below shows a solid-state relay and the control wires. The red (+) wire connects to D4, and the black wire connects to GND, both on the 15-pin connector on the back of the EP series of Volteq DC power supplies.

The top two connectors are for the output, and the + terminal should connect to the positive output terminal of the power supply, and the – terminal should connect to the load in series.

Results

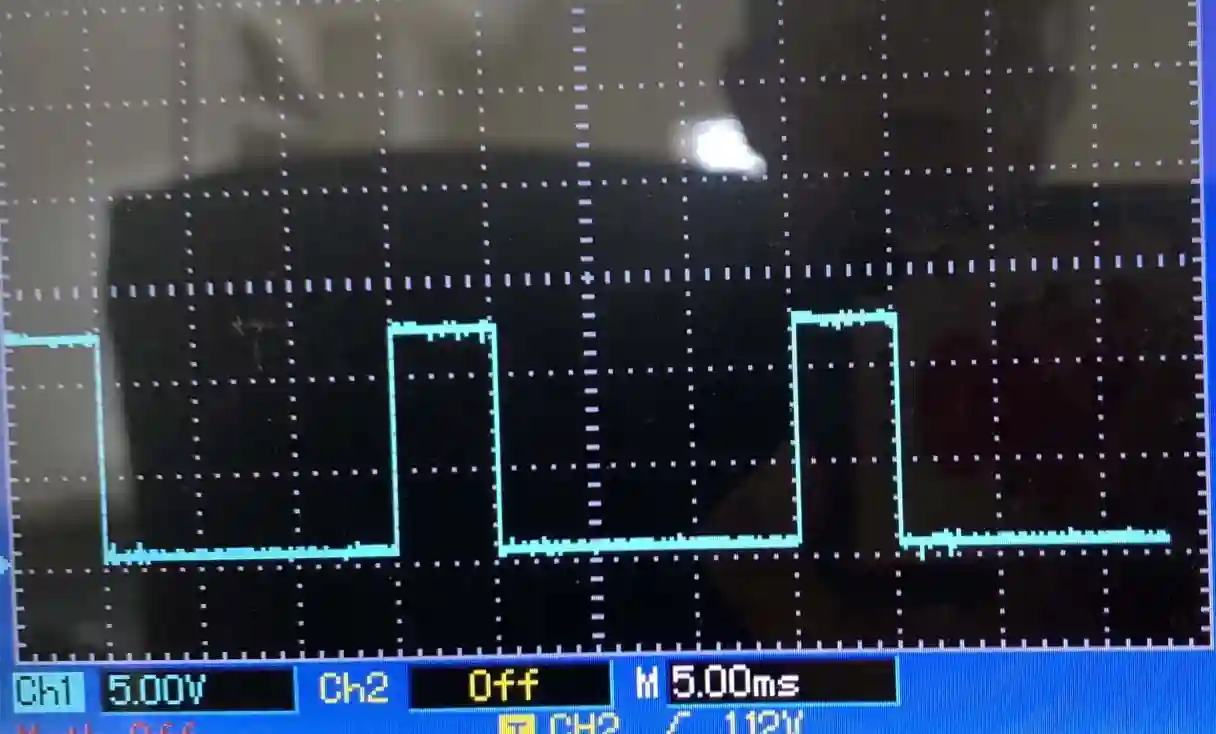

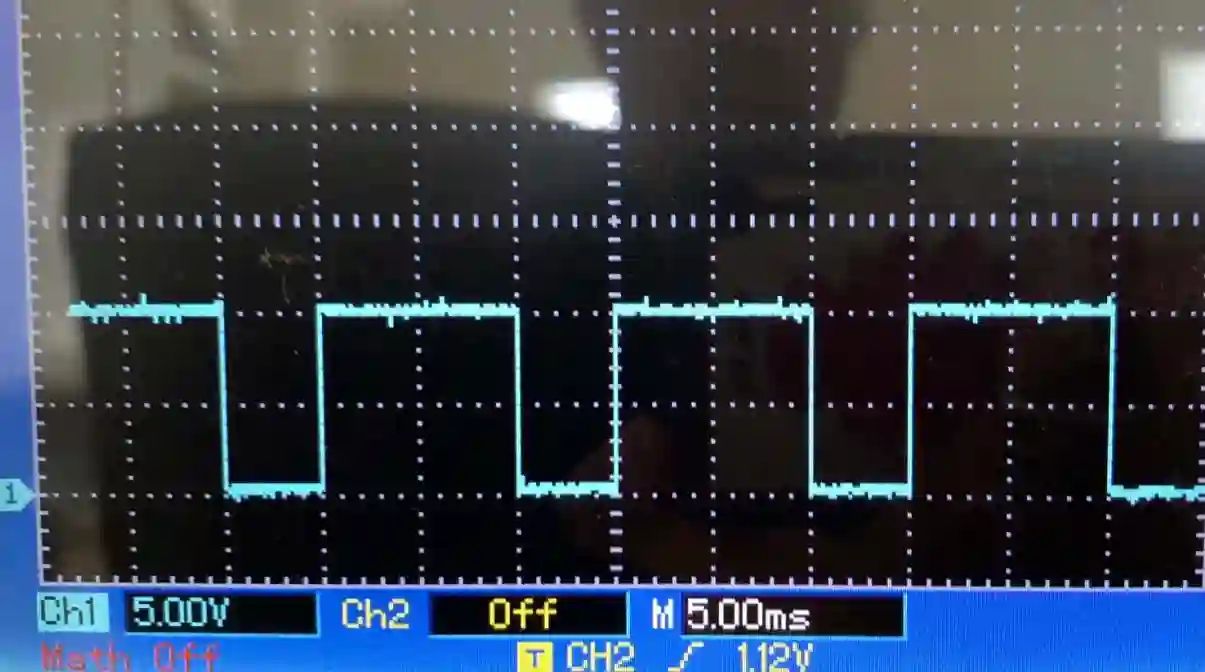

Below we show two pulse outputs as examples.

A 12V pulse train with 5ms ON and 15ms OFF.

A 10V pulse train with 10ms ON and 5ms OFF.

We will cover other application examples in future blogs. Please check back for updates.