Custom Rectifiers

Volteq specializes in custom-designed and manufactured DC power supplies and industrial rectifiers that can deliver up to 20,000 Amps and 200 Volts.

Our power supplies are widely used in a variety of industries, including surface finishing (such as plating and anodizing), wastewater treatment through electrocoagulation, electrolysis, aviation, and corrosion management. In addition to these applications, our custom DC power supplies have been successfully utilized in a range of industries, including resistive heating, DC motors, battery charging, and more.

What's new?

- Rapid Response: 8 New Custom Rectifiers Delivered in Record Time

- Volteq Delivers Two High Power Custom Rectifiers to Satisfied Customer

Why Choose Volteq for Your Critical Application?

| Key Considerations | Volteq Advantages |

|---|---|

| Deep Knowledge and Knowhow | Volteq has over 40 years experience in designing and manufacturing DC power supplies for industrial applicaitons, with special deep domain knowledge in electro-plating and anodizing rectifiers for surface finshing industry. |

| Scale and expertise | Experience in small and large orders; end-to-end logistics services. |

| Fast Delivery | Typical production time for custom orders is 2-3 weeks; shipping is another week or so depending on the mode of transportation. |

| Best Technology | Our rectifiers are made with state of the art IGBT and SCR technology for 90%+ efficiency, with advanced control options. |

| Focus on Value Creation | Continued investments in desgin and manufacuring ensures that we can deliver high quality reliable rectifiers at an affordable price. |

| Best Service | Knowledgeable and dedicated associates are available during each step to ensure smooth delivery and installation of your order. |

How to Select a Custom Rectifier: Key Factors to Consider

| Factor | Description |

|---|---|

| Current and Voltage Requirements | Carefully calculate and plan for the maximum voltage and current needed for your application. For example, in eletroplating applications, the maximum voltage typically doesn't exceed 12V, and the maximum current is proportional to the surface area of the parts to be plated. Add 10-20% to the maximum current for leeway. |

| Efficiency | Choose a rectifier with high conversion efficiency to minimize energy and operating costs. Look for state-of-the-art technology, such as IGBT or SCR, with an efficiency of over 90%. |

| Input AC | For mid- to large-sized rectifiers, choose 3-phase 208V or 480V AC input. For applications needing less than 500A, single phase 120V or 220V is an option. |

| Cooling | Rectifiers are available with both air and water cooling options. |

| Control | Rectifiers can be controlled from the front panel or through a controller box attached to the unit. A timer function is typically included, with additional controls such as ramp, reverse polarity, and PLC (for computer control) available as optional features. |

| Ripple Noise/ Safety | Different applications have different level of tolerance on ripple noise. While plating and anodizing are generally quite tolerant to ripple noise, other applications may demand tighter ripple control; cost can vary depending on the ripple level. Ensure the safety of your equipment and personnel with standard features such as over-voltage, over-current, over-power, and over-heat protection. |

| Price and Reliability | Investing in a high-quality, reliable rectifier can save you money in the long run by reducing maintenance costs and avoiding costly downtime; you can achieve that without breaking your bank by choosing your supplier wisely. |

| Reliable Supplier | Investing in a reliable supplier with long history ensures that you will receive a quality product and reliable service when you need it. Volteq has 40+ years of crafting custom rectifiers for industrial applications, and over 20 years of experience in serving the US market. |

How to order a custom rectifier?

Step 1: Email us at support@volteq.com for a quote with your complete requirements, which typically should include:

Maximum voltage and current required.

AC input choice (three/single phase, 480V, 380V, 240/208V, etc.).

A simple description of your application.

You may also specify optional features such as PLC capability, reverse polarity, ramp, reduced ripple noise, amp-hour meter, etc.

Step 2: A quote will be generated within a day or two.

Step 3:Once our proposal is accepted, we need 50% down payment to start the production, which typically takes 2-3 weeks and 7-10 days to deliver. All in all, you may have your own custom rectifier within 3 weeks!

Please feel free to call us at (408)622-9851 to consult with our knowledgeable staff at any time!

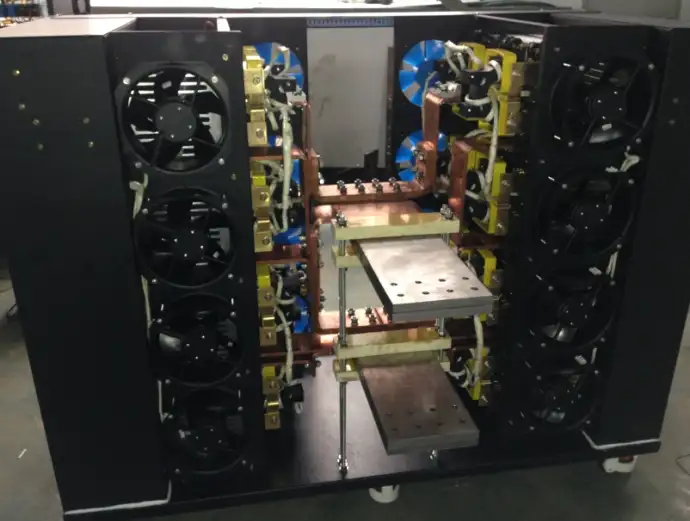

Examples of recently shipped custom rectifiers